Most of the production losses incurred during the planned maintenance activities can be brough down substantially. AlgoAPM® has embedded energy forecasting functionality by carefully planning a maintenance activity around the forecast.

Together with the expected energy inputs, the inputs from turbine and EBoP Scada, the APM measures all sources of lost production and objective is to reduce the losses and increase production.

Together with the expected energy inputs, the inputs from turbine and EBoP Scada, the APM measures all sources of lost production and objective is to reduce the losses and increase production.

The APM has investigation tools that are capable of detecting repetitive faults. The tools also make it clear whether the fault is on a specific turbine or whether all turbines are impacted with a serial defect

There are several predictive maintenance algorithms that provide action recommendations; e.g blade wear, soiling and icing e.t.c usually a couple of weeks in advance. If timely actions are taken, the incidents of turbine breakdowns are reduced substantially.

There are several predictive maintenance algorithms that provide action recommendations; e.g blade wear, soiling and icing e.t.c usually a couple of weeks in advance. If timely actions are taken, the incidents of turbine breakdowns are reduced substantially.

Get in touch with us today to start a conversation about how we can collaborate, innovate, and achieve success together. Whether you have a specific project in mind or just want to learn more about our services.

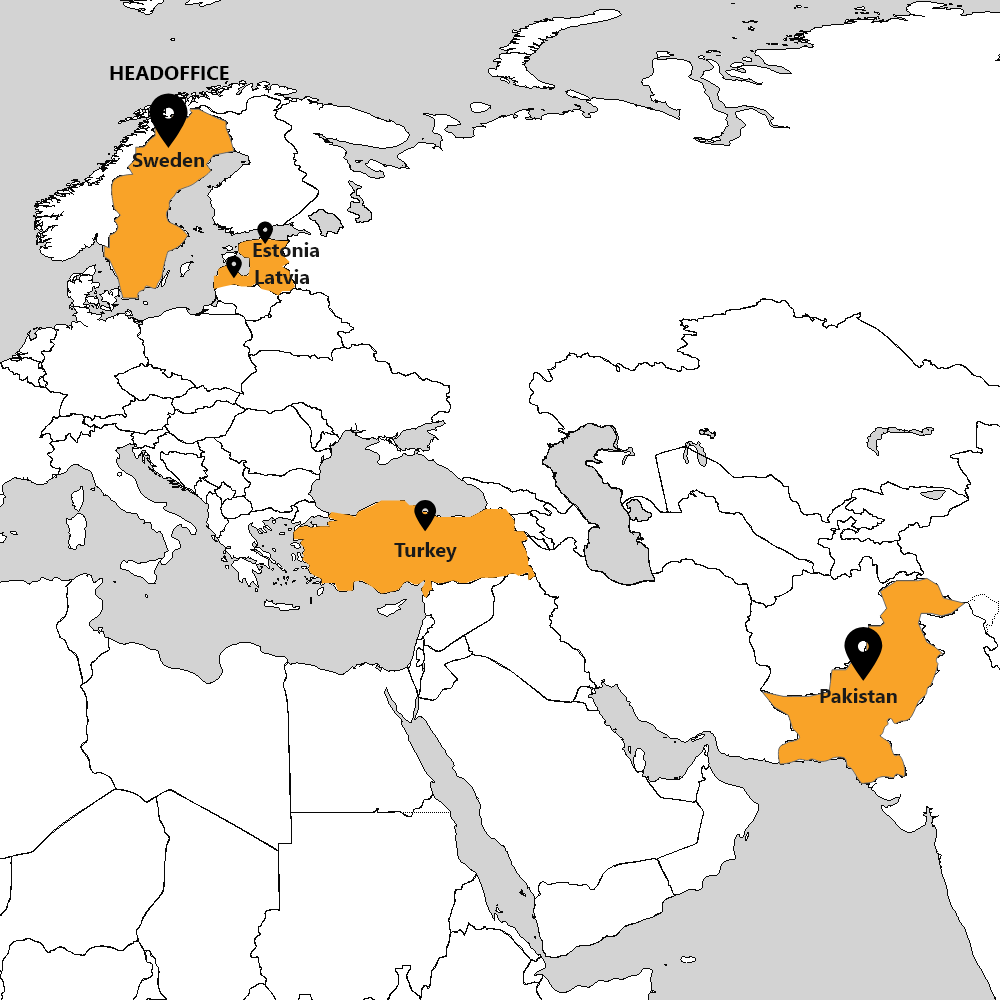

Algorithm Energy AB is a specializing in advanced algorithms for Wind energy management and optimization. It develops software solutions that use sophisticated algorithms to analyze wind energy production and prevent losses.

Copyright © 2024 Algorithm Energy AB. All Rights Reserved.