Drive train condition monitoring software takes input (vibrations) from the accelerometers installed at drive train, processes their signals further using several sophisticated proprietary techniques to predict any impending gearbox failures.

We look for signs of failure at much lower detection thresholds. With greater focus and lower thresholds of detection, probabilistically, we can pick up gearbox faults much earlier. Thus, we are in a better position to avert a repeat of gearbox disasters.

ALGO team has developed the capability of interpretation of results from condition monitoring system.

Our Engineers monitor the turbines daily to look out for gearbox fault frequencies. If there is a slight change in amplitude, then it will be investigated thoroughly. Finally, the results of analysis is shared along with recommendations.

We provide weekly and monthly reporting regarding status of turbines. It will cover the following

Current State | Fault Development | Life Expectancy | Intervention Required

If there is a fault being developed at a drive train is discovered during routine surveillance, it will be reported right away. We also provide the post replacement analysis of components

Get in touch with us today to start a conversation about how we can collaborate, innovate, and achieve success together. Whether you have a specific project in mind or just want to learn more about our services.

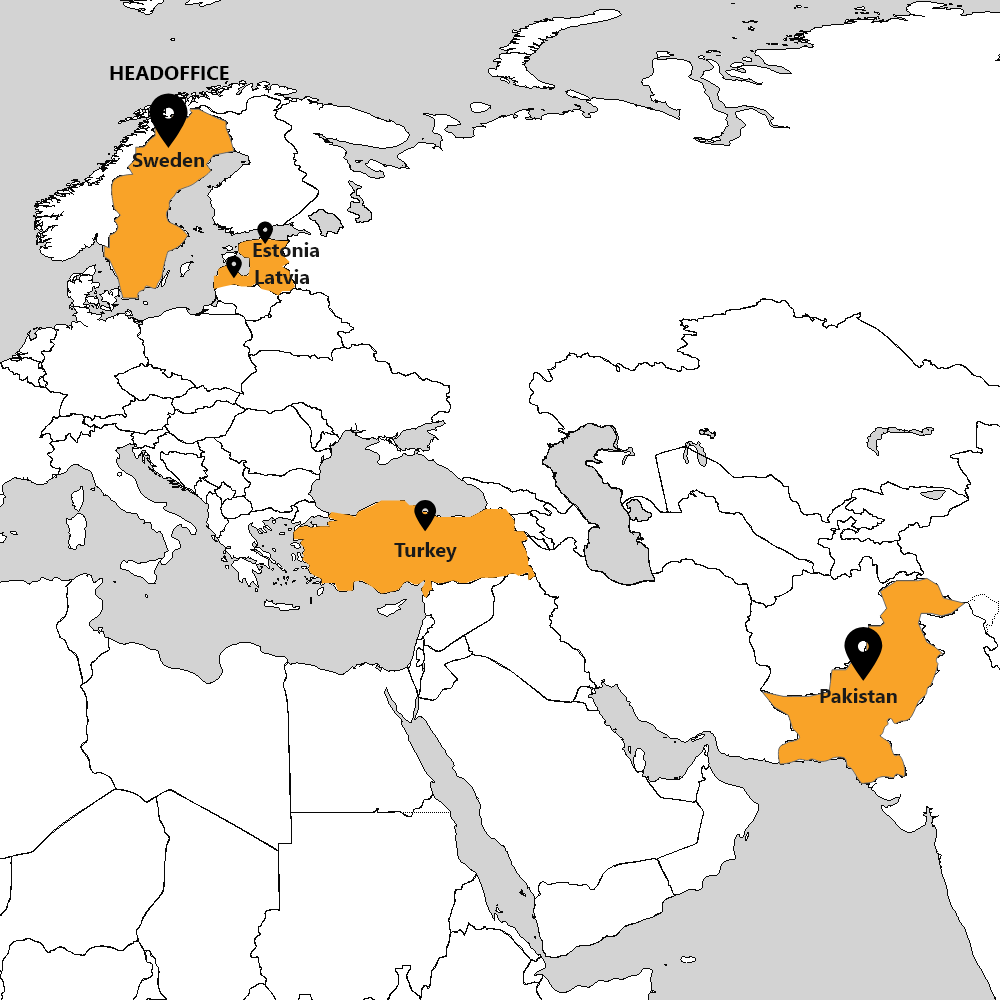

Algorithm Energy AB is a specializing in advanced algorithms for Wind energy management and optimization. It develops software solutions that use sophisticated algorithms to analyze wind energy production and prevent losses.

Copyright © 2024 Algorithm Energy AB. All Rights Reserved.